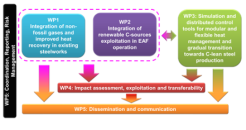

Project description

Electric arc furnaces to reduce steelmaking emissions

The EAF-based steelmaking plays a fundamental role in the decarbonization of steel production, being at the core of the “circularity of steel” as well as strategic for the application of CDA and SCU technologies. The average potential CO2 savings in EAF-based steelmaking is related to the integration of non-fossil and renewable energy sources, modular heating technologies and alternative heat recovery.